Fast and high-quality metal production with tradition

Edge deburring and part tumbling

We can deburr edges and tumble parts of any materials.

Edge deburring

We will deburr edges of all materials using machine deburring systems – up to the maximum part size 1 100 mm, manually – larger part sizes.

Odjehlovací stroj RWT STEEL LINE série 180

The machine provides for the machine pull through deburring:

- Deburring after die cutting, pressing and chip machining

- Removal of scale and plasma burning, laser and oxygen cutting oxides

- Making surface qualify uniform prior to further processing

- Edge chamfering and rounding

The machine has 4 modular units for deburring variability and quality.

Deburring machine SWING GRINDER

This machine is used to deburr smaller batches or big size parts where manual tools are not recommended to be used (for time, total cost or complexity reasons).

An advantage of this machine is uniform processing of all parts´ edges.

Machine features:

- Deburring after cutting, pressing and chip machining

- Removal of scale and plasma burning, laser and oxygen cutting oxides

- Making product surface uniform prior to further processing

- Edge chamfering and rounding

Part tumbling

We tumble part of all types of material up to the size of approx. 300 mm.

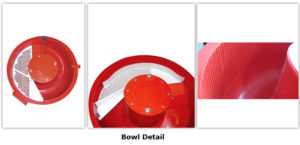

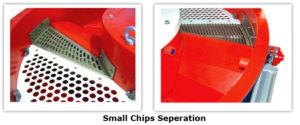

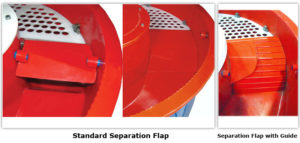

Tumbling machine ERBA EVP-RA-200

For tumbling, we use the machine ERBA with separation sieve and drier. It can be used when we need to produce smooth surface and remove all burrs on exterior and interior edges.

What can be tumbled are metals, plastic, rubber, jewels and other materials.

Finish: The deburring and tumbling technology allows for the use of all finishing operation types. Read more »

Quality guarantee

- We use only specified grinding types for each material in order to void material contamination.

- After each deburring cycle, we flush the tumbling fills and bodies.

Production deadlines

Edge deburring and part tumbling will be completed in 5 business days.

Production inquiry

We will prepare an individually tailored price quotation for you.

Contact person: Michal Pazour, pazour@kovo-klobas.cz, +420 724 117 922.