Fast and high-quality metal production with tradition

Bending

Do you need to bend some sheets or profiles? We bend products on press brakes and bending centre.

Press brake sheet bending

Materials we bend on press brakes include:

- All types of materials that can be bent.

- Sheets up to 3 meters long and 12 mm thick.

During the bending operation, we can carry out sensor based measurement.

We do not bend checkered (nonslip) sheet material.

Press brake Trumpf TruBend 5085

Thanks to its rear stop variable systems, this press brake can machine many various parts.

- In its class, it can manufacturethe widest part spectre.

- In its class, it offers maximum working precision.

- The ACB speed function = metering of precise angle starting from the first part at full machine production speed.

Thanks to the shift of the bottom tool, it can carry out special applications (e.g. folding).

| Pressing force | 850 kN |

|---|---|

| Folding length | 2 020 mm |

| Užitečná montážní výška | 445 mm |

| Overhang | 420 mm |

| Accelerated operation | 220 mm/s |

| Maximum working speed | 10–20 mm/s |

| Number of CNC controlled axes | 5 |

Press brake Trumpf TruBend 5170

Productive all-round machine

The TruBend Series 5000 is TRUMPF’s most successful bending machine worldwide. Using it, your production will be unrivalled – from programming, to setup, to the actual bending. Innovative

features such as the lower tool displacement and the 6-axis backgauge provide you with complete production freedom.

| Pressing force | 1 700 kN |

|---|---|

| Folding length | 3 230 mm |

| Useful assembly height | 615 mm |

| Overhang | 420 mm |

| Accelerated operation | 220 mm/s |

| Maximum working speed | 25 mm/s |

| Number of CNC controlled axes | 6 |

Press brake Trumpf TruBend 7036

It ranks among fastest machines. It shows high pressing ram and rear stop acceleration.

- Lightweight carbon fibre elements in the rear stop finger.

- Gearless direct electric drive of the pressing ram.

We use this brake first of all for the production of smaller parts where precision and speed is required.

| Pressing force | 360 kN |

|---|---|

| Folding length | 1 020 mm |

| Useful assembly height | 295 mm |

| Overhang | 150 mm |

| Accelerated operation | 220 mm/s |

| Maximum working speed | 10–25 mm/s |

| Number of CNC controlled axes | 4 |

Press brake Trumpf TruBend 7050

High-speed machine for bend small and medium-sized parts.

| Pressing force | 500 kN |

|---|---|

| Folding length | 1530 mm |

| Useful assembly height | 385 mm |

| Overhang | 250 mm |

| Accelerated operation | 220 mm/s |

| Maximum working speed | 10-25mm/s |

| Počet řízených CNC os | 6 |

Press brake LVD PPEB 135/30

Its excellent for bending of high and deep switchboards.

Turbo functionality = high bending rate.

We use this press brake mainly for the production of switchboards and profiles up to 3 meters of length.

| Pressing force | 1 350 kN |

|---|---|

| Folding length | 3 020 mm |

| Useful assembly height | 500 mm |

| Overhang | 400 mm |

| Accelerated operation | 180–220 mm/s |

| Maximum working speed | 10–22 mm/s |

| Number of CNC controlled axes | 5 |

Press brakes LVD PPEB 80/25

It is excellent for bending of larger series of longer parts.

It shows high production precision.

This press brake is used primarily for the production of switchboards and profiles up to the length of 2.5 meters.

| Pressing force | 800 kN |

|---|---|

| Folding length | 2 520 mm |

| Useful assembly height | 400 mm |

| Overhang | 400 mm |

| Accelerated operation | 130 mm/s |

| Maximum working speed | 10 mm/s |

| Number of CNC controlled axes | 4 |

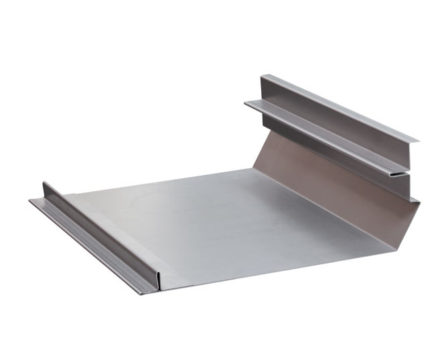

Bending centre sheet bending

On the bending centre, we bend sheets and profiles:

- up to the maximum length of 2 meters,

- up to the maximum thickness of 2 mm.

This process does not make it possible to manufacture narrow profiles.

Bending centre production advantages:

- We guarantee post-bending part width with the tolerance of +/-0.2 mm.

- We create composed radius by a big number of small bends.

We bend painted sheets, too.

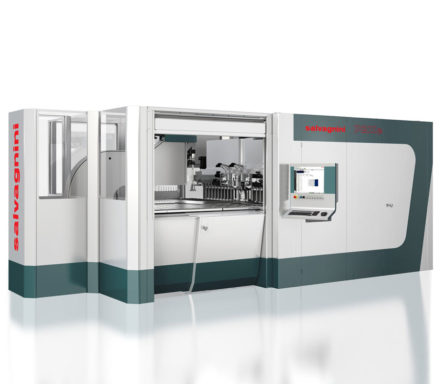

Bending centre Salvagnini P2Xe

Bending process automation: We bend parts based on prepared programme including follow up automatic correction based on actually measured sheet thickness.

Any number of bends (upwards and downwards) may be done on any side to be bent including various radiuses or 180 ° bends (folding).

We use this machine booth to process large batches and production of small series.

| Maximum thickness | 2 mm |

|---|---|

| Maximum length | 2 m |

| Bent length tolerance | +/-0,2 mm |

| Bent angle tolerance | +/- 1° |

Finish: The bending process makes it possible to use all finishing operation types. Read more »

Quality guarantee

- We calibrate machines and their metering system before we start the production.

- We use professional metering systems.

- We use auxiliary inspection gauges.

Production deadlines

We will produce standard burnt or cut parts for you in 5 business days.

Source documents for the production have to be delivered in formats DXF, DWG or STEP. Do you need advice? We will design your product using the Solid EDGE software.

Production inquiry

We will prepare an individually tailored price quotation for you.

Contact person: Libor Pazour, lpazour@kovo-klobas.cz, +420 724 845 067.